Antipolo City is located in the northern half of Rizal Province, which is within the eastern boundary of metropolitan Manila in the Philippines. Antipolo City is the second largest city in Rizal Province, with a total land area of 38,575 hectares. The topography is rugged, rising from the coastal plain at elevations of about 6 to 12 meters above sea level in the Mayamot area up to 300 meters on the eastern border. The new Manila Water Optimization System benefits more than 709,000 people, equating to more than 140,000 households.

Manila Water Company’s goal for the Antipolo water supply system optimization project encompassed preparation for the anticipated rapid growth from a current population of 656,000 people to 2.2 million by 2022; evaluation of the steady state and transient hydraulics of the preferred pipeline, pump station, and reservoir combination; and overall improvements to the reliability and efficiency of the Antipolo network system.

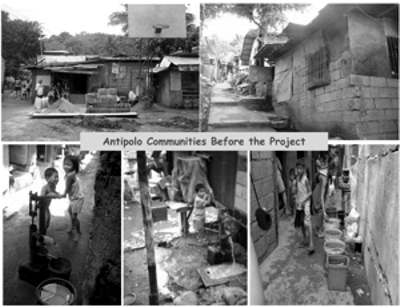

The project presented some interesting complications. First, the 1,200-millimeter suction line had limited capacity, so it served as a constraint to maximizing the output of the first pumping station in Kingsville. Second, the hilly terrain of the Antipolo area presented difficulties in designing the water distribution system because its topography ranged from elevations as high as 300 meters to as low as 20 meters above sea level. And lastly, communities living in the area of expansion consisted mostly of low-income families who had received their water supply from shallow wells, private deep wells, and water delivery trucks, which imposed health risks.

To overcome these challenges, Manila Water created a hydraulic model of the Antipolo water system. Hydraulic and transient simulations were conducted to analyze network constraints and identify possible solutions to improve the performance of the network. Based on these simulations and intensive field investigation, network improvement projects were conceptualized, designed, and implemented.

The hydraulic network model was calibrated in WaterGEMS based both on field data and the existing network database. Hydraulic and transient simulations using WaterGEMS and HAMMER helped to locate critical locations in the system, and strategies to control potential transients were identified through appropriate flow-control operations and the installation of surge-protection devices. Pump operation schedules were also simulated using the model to come up with the most efficient scheme.

Manila Water also successfully implemented a program to develop a water service connection scheme for low-income customers. This flagship project is called Tubig Para sa Barangay (TPSB). Sixty-three millimeter HDPE pipes were laid on the narrow streets of the communities that would receive the new potable water service. Service connections and water meters were installed in groups to save space and cost. The type of service connection ranges from individual to shared (1 meter serving four to five families) and bulk (community service with a mother meter).

Christine Aubrey Nocum, network systems manager at Manila Water, explained, “With its impressive capability to integrate with our company’s existing software applications, WaterGEMS and HAMMER made it much easier for us to design and manage our water network as we continuously expand our services and improve the lives of our customers.”

This project benefited a total population of more than 709,000 people, which equates to more than 140,000 households. It will benefit 3,000 more households upon completion of the network’s expansion. The completion of the network improvement project for the Antipolo water system will not only improve the water supply and pressure in the area, but, more importantly, the quality of life of the people of Antipolo.

The TPSB project paved the way for low-income families of the mountain communities to have their own water service connections at a significantly lower cost. The project has also improved the health of the people in the TPSB communities, since they no longer drink water from deep wells and water delivery trucks. Statistics show that diarrhea and cholera outbreaks in the TPSB communities have decreased significantly.

“The use of Bentley products has given our company savings in terms of both time and money. With WaterGEMS and HAMMER, the interface to GIS data is already built in, unlike other brands where you need to buy separate software for the GIS interface. The average time to create the model was two to three months using other software, compared to just two weeks to one month using WaterGEMS and HAMMER,” Nocum concluded.

“With the creation of the Antipolo water system’s network model using WaterGEMS and HAMMER, network improvements and the associated projects were identified and implemented, which resulted in savings on both capital and operational expenditures.”

The installation of surge protection apparatus such as PRVs and SAVs at strategic locations identified from the network model decreased the incidents of water interruption due to pipe breakages from an average of six breakages per month to zero to two breakages per month. This resulted in a decrease in leakages of 6.3 milliliters a day, or an equivalent amount of saving of almost $75,000.

Furthermore, adjustments to the pump operation plan that were developed based on the hydraulic model and field studies decreased the pump station operating expenditure by almost $7,000 per month. Water availability also improved from 18 hours per day to 24 hours per day. In summary, with the network improvements in the Antipolo water system, the people of Antipolo can now enjoy clean and potable water.

————————————————————————————————————-

Authored by Perrine Parrod, Bentley’s Marketing Program Manager, Water.