By John Anderson, Strategic Business Development, FLIR Systems Inc.

A new tool is making roof inspections safer, faster, and more efficient by reducing the need for dangerous treks up and across rooftops. Many roof inspectors are now investing in unmanned aerial vehicles (UAVs)—commonly known as drones—equipped with thermal and visible cameras so they can more easily track down moisture under roof membranes or find indications of missing or damaged insulation.

A new tool is making roof inspections safer, faster, and more efficient by reducing the need for dangerous treks up and across rooftops. Many roof inspectors are now investing in unmanned aerial vehicles (UAVs)—commonly known as drones—equipped with thermal and visible cameras so they can more easily track down moisture under roof membranes or find indications of missing or damaged insulation.

Drones equipped with cameras can fly over large areas and provide a thorough view of an entire roof. This allows the roofer or roof inspector to determine which sections are performing well, and which need further investigation. They may still need to get up on the roof and use traditional (often destructive) test methods to quantify the extent of a problem, but the overall time needed from initial scan to diagnosis is greatly reduced.

Who is qualified to inspect roofs?

The laws, regulations, and codes that define who can make a diagnosis or recommendation on roof damage and repair vary from state to state, so drone operators should become familiar with their local requirements. That is why it is imperative that drone operators always work with a licensed professional to ensure that their scans hold real, actionable value. This article assumes users of drones with thermal imaging cameras follow this practice.

There is also a national standard defining the methodology that should be followed by thermographers who use handheld cameras to inspect commercial roofs. This standard—ASTM c1153-10 (2015), Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging—also applies to drone operators. The recommended practice is to inspect an hour after sunset, so there is usually a need for a daytime waiver from the FAA.

Advantages of using drone technology paired with thermal and visual imaging

Combining the use of drones, thermal, and visual cameras has several advantages over other options. Drones can be flown from a controller or execute a pre-programmed flight route.

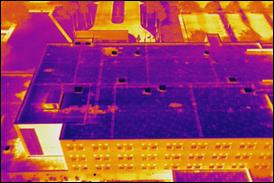

Adding thermal imaging cameras to drones allows inspectors to scan large areas for moisture trapped underneath roof membranes, and look for the effects of structural issues such as missing insulation. The presence of water and the absence of insulation can both cause changes to the surface temperature of the roof. The thermal camera detects this temperature difference and displays it as colors—for example, dark tones indicating cold moisture or light tones indicating heat escaping through the uninsulated roof. Finally, the camera does not require visible light, so flights can take place at night or in areas that are shadowed.

Adding a visual camera to the drone-thermal camera duo brings additional perspective to roof inspections. They can fly pre-set flight missions to capture high-resolution roof imagery that can later be stitched together into a 3D model or ortho-mosaic. Inspectors can then use these images to determine whether there are any defects, broken tiles, missing shingles, or other problems. Insurance adjusters also benefit from the documentation and surety of drone inspections of roofs.

Adoption, cost, and other considerations

Of course, every business should consider the time and financial costs of adopting new capabilities before making an investment. For drone and thermal camera technology, one challenge to adoption is operator knowledge. Operators need training to fully grasp the variables that affect the accuracy of a thermal image and to understand how to interpret thermal imaging information. However, there are useful educational resources. The Infrared Training Center offers specialized courses in drone thermography and roof inspection to help operators both properly analyze the images they capture and record accurate temperature measurements.

One important step in the training process is understanding how the camera “sees” different roof materials. For example, some materials, such as wood shingles, can absorb and emit energy, while others, such as metals, will reflect energy. Understanding how each of these materials will look in thermal will help inspectors better interpret their images.

An important factor when deciding whether to embrace drone technology is expense. Operators practicing commercial inspections can recoup this cost fairly quickly. Those doing residential inspections can as well, depending on volume. It is not priced for the conscientious homeowner who wants a tool for inspecting their own house.

Beyond training and cost, in some areas there is the regulatory hurdle of beyond visual line-of-sight (BVLOS) requirements. When one flies over a flat roof while standing on the ground, the aircraft may be shielded from direct observation. Such flights would require a waiver from the FAA, or possibly additional visual observers to complete legally.

What to consider when selecting thermal imaging cameras for use with drones

Typically drones and thermal cameras are not manufactured and designed as a single unit; rather, drones are made to hold several different types of cameras, and thermal cameras are made to be held by a variety of drones. A wide variety of drones with differing levels of sophistication can be used for roof inspection, but there are fewer thermal cameras that are right for the job.

FLIR manufactures several types of thermal cameras that are both drone-agnostic and plug-and-play with systems made by DJI Innovations. FLIR’s Duo Pro R and DJI’s Zenmuse XT2 cameras are both equipped with thermal and RGB (visible) cameras that are calibrated to overlap one another. This allows inspectors to get both types of imagery in a single flight and overlay these images to better identify problematic areas.

FLIR cameras also feature MSX (Multi Spectral Dynamic Imaging), an imaging technology that embosses thermal photos with details from a visual image. This allows users to see words, serial numbers, patterns, and other attributes otherwise missed by thermal imaging.

Ease-of-use is a major consideration. A simple, flexible user-interface with features to get the job done should be a selection criterion for any business thinking about implementing a new technology. In addition, potential buyers should look for a company with the infrastructure to adequately support the products over their lifetime.

FLIR’s ready-to-fly UAS Thermal Imaging Kits are configured for ease-of-use and include DJI airframes and Zenmuse XT2 cameras. By combining the flight stability, gimbal technology, and mobile app integration of DJI drones with the thermal imaging technology of FLIR, these kits offer a solution for reliable, rapidly deployable aerial thermal imaging. With the FLIR kits, it’s a one-stop-shop with everything the user needs to take flight, but FLIR additionally offers drone solutions for existing owners as well, offering a solution dependent on each individual pilot’s needs.

Drone/camera combinations make inspections faster and safer

While drones can face regulatory challenges concerning where and when they can fly, the combination of drones with thermal and visual cameras is a must-have for roof inspectors who want to stay ahead of the curve. These systems can make inspections faster and more efficient, while also reducing safety concerns. To get the most out of an investment in drone and thermal imaging technology, training, and an understanding of local regulations are key. Select the right user-friendly equipment that is well supported, and your investment can pay dividends for years.

There are no upcoming events.