Located on the Claro River in Brazil, the 90-megawatt Barra dos Coqueiros hydroelectric power plant will generate energy for 650,000 people in the state of Goias. It is one of two new hydroelectric plants being put into operation in April 2010 by the Gerdau Group, the leading manufacturer of long steel in the Americas. The $230 million investment represents the company’s expanded commitment electricity generation from renewable sources.

Located on the Claro River in Brazil, the 90-megawatt Barra dos Coqueiros hydroelectric power plant will generate energy for 650,000 people in the state of Goias. It is one of two new hydroelectric plants being put into operation in April 2010 by the Gerdau Group, the leading manufacturer of long steel in the Americas. The $230 million investment represents the company’s expanded commitment electricity generation from renewable sources.

Public- and private-sector investment in energy infrastructure is a critical component of Brazil’s Growth Acceleration Program initiated in January 2007 by President Luiz Inacio Lula da Silva with the goal of raising average GDP growth to 5 percent per year. Brazil is expected to invest about $32 billion per year over 25 years to expand its energy supply, with 35 percent of funds going to hydroelectric projects.

The infrastructure investments align with Gerdau’s strategy to fund construction projects built with steel manufactured by Gerdau mills. In 2007, the National Electrical Power Agency granted a hydroelectric production concession to the company’s subsidiary, Gerdau Acos Longos S.A., which committed to begin operations at the Coqueiros complex by 2010.

Engevix, the leading consulting engineering company in Brazil, was retained to perform engineering design of two plants with an installed capacity of 155 megawatts (Coqueiros with 90 MW and Cacu with 65 MW).

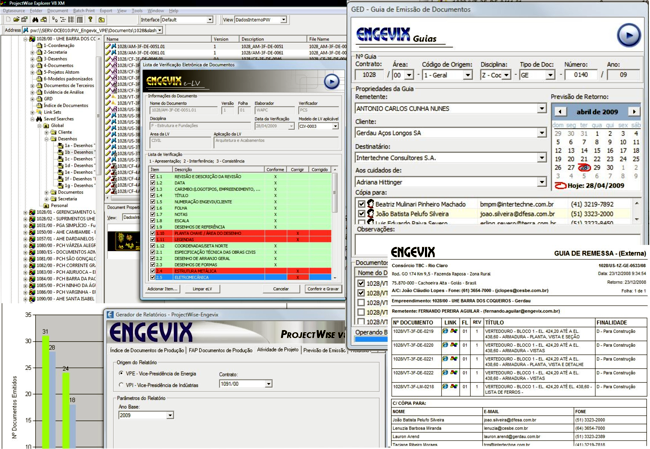

To meet the aggressive schedule, Engevix deployed professionals in multiple offices, some in cities 700 miles apart. ProjectWise enabled the geographically dispersed team members to access up-to-date project information. “Engevix was already accustomed to working with geographically dispersed teams, but we knew that we could improve our communications and provide a better way to access project information,” said IT Director Ciro Julio Schmitt.

“We had experienced challenges in the past with few professionals available in certain regions. We were looking for an opportunity to better optimize our distributed work force.”

Using ProjectWise allowed Engevix to deploy available professionals at other offices without incurring the expense of moving them to the work site in Cachoeira Alta or all together in the same office. Participants in Brasilia and Florianopolis contributed to project design and management. The owner’s engineering service was executed by a company from Curitiba. A key equipment supplier was located in Sao Jose dos Campos. And the client contact was based in Porto Alegre. ProjectWise was critical to integrating these offices.

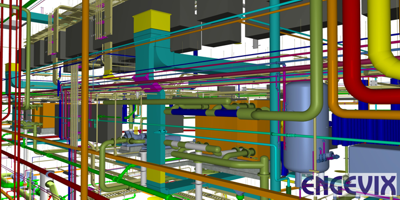

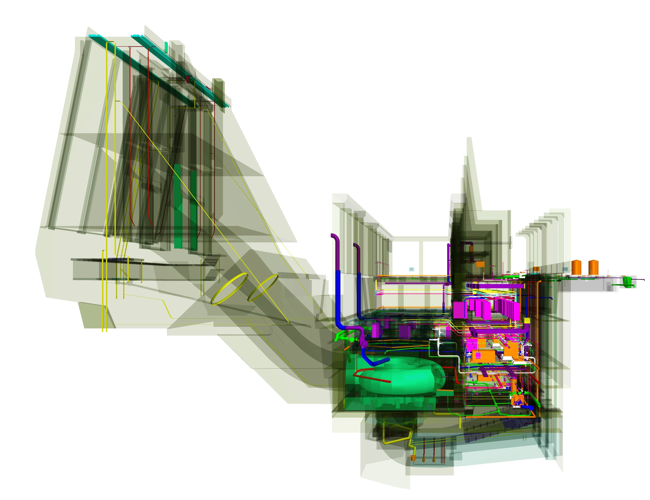

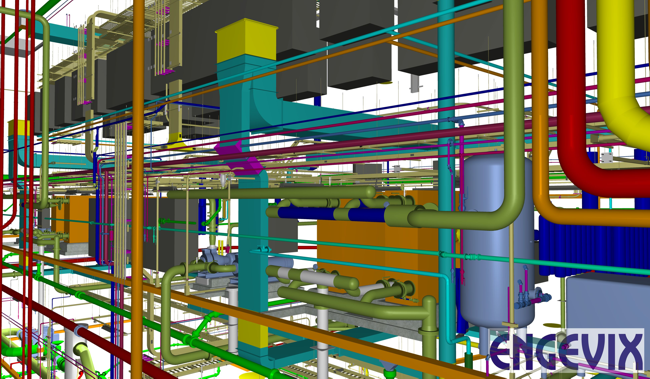

ProjectWise not only provided engineering content management, but it also served as a collaboration platform that allowed design disciplines to integrate their work products. Using 3D design applications, the geotechnical, electrical, mechanical, and structural designs were seamlessly integrated. “The geographical location was no longer a problem. Anyone could perfectly contribute to the project and interact with colleagues anywhere,” Schmitt said.

Engevix estimated that optimized workflows reduced production time by approximately 40 percent. Of course, these efficiencies were not accomplished overnight. Engevix had to train nearly 600 people on staff to use the new solutions. More than 1,000 hours were expended in training for Engevix design professionals through product training, online seminars, and self-paced multimedia materials.

In the process of deploying the collaboration technology and integrated design applications, Engevix evaluated existing workflows and made changes to improve efficiency and productivity. Adjusting to the virtual environment required many adaptations, such as redlining on screen instead of on paper. Automated messages improved communication among team members and workspaces were standardized to facilitate collaboration.

Customized tools addressed quality-control issues. For example, Engevix converted a manual quality-control checklist to an electronic format that provided intelligent control over when documents were released and to whom. Another customized tool automated transmittals to clients, making document delivery agile and reliable.

Hundreds of 2D drawings automatically extracted from 3D models allowed quick delivery of accurate section cuts, plans, and details. Within this controlled environment, any necessary revisions were made at 50 percent less cost compared to the firm’s previous method.

The interoperability of Bentley applications with other platforms also eliminated problems in exchanging information with contractors and others. “When Engevix received documents, mainly from equipment suppliers, it was quite easy to attach and integrate with our documents because all the different formats were supported,” said Henrique de Britto Farias, IT manager and Engevix’s ProjectWise Coordinator. “We also distributed Bentley View and Redline to our partners. When necessary, we converted our 3D DGN drawings to DWG.”

Working with 3D design tools in an integrated environment boosted design production and quality in several ways. Synergy among design disciplines improved, with professionals referencing their colleague’s work as a matter of course. As a result, misunderstandings decreased. Sheet production was up to 50 percent faster and rich detail easily attached to each sheet for reference during construction.

Project reports generated for senior management provided a timely and complete overview of the project status so adjustments could be made as needed to meet project milestones.

With construction under the supervision of a consortium (Toniolo, Busnello, and Cesbe), the hydroelectric plants were delivered on schedule, according to the National Electrical Power Agency. The plants were designed to provide a clean, sustainable, and environmentally sound source of energy for the municipalities of Cacu and Cachoeira Alta. Just at the owner’s investment in hydroelectric power plants contributed to the future vitality of the Brazil economy, Engevix’s investment in an integrated design environment built a solid platform for future infrastructure projects.

——————————————————————————–

Cathy Chatfield-Taylor is a freelance writer/editor for the infrastructure engineering and construction industry and a frequent contributor to Be Current magazine, a Bentley publication. She is a member of the International Association of Business Communicators. Contact her at [email protected].